H2 production with wastewater

污水电解制氢

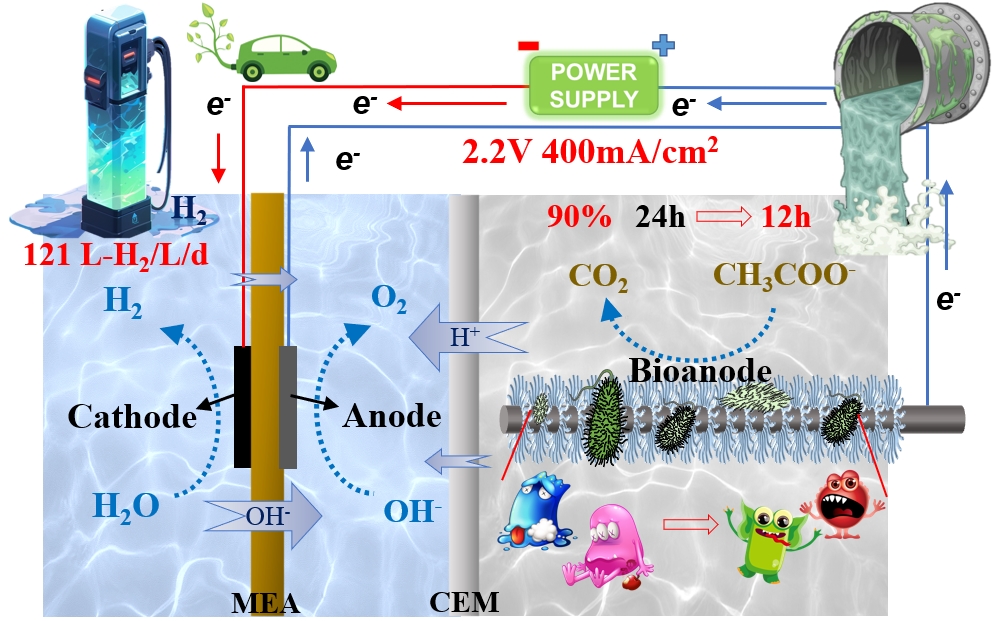

The world today faces serious environmental pollution and energy shortage issues. Utilizing wastewater electrolysis for hydrogen production can achieve sustainable clean energy production while repairing the environment. On one hand, our microbial water electrolysis cell system, which integrates water electrolysis and microbial electrolysis cell technologies, is promising for industrial-scale current density hydrogen production and wastewater treatment. On the other hand, in microbial electrolysis cells, through the optimization of catalysts, electrode materials, reactor structures, and electricity-producing bacteria, combined with 3D printing technology, there is potential to enhance the wastewater treatment and hydrogen production performance of the microbial electrochemical system.

Carbon dioxide conversion by electrochemical and microbial processes

二氧化碳的电化学和微生物转化

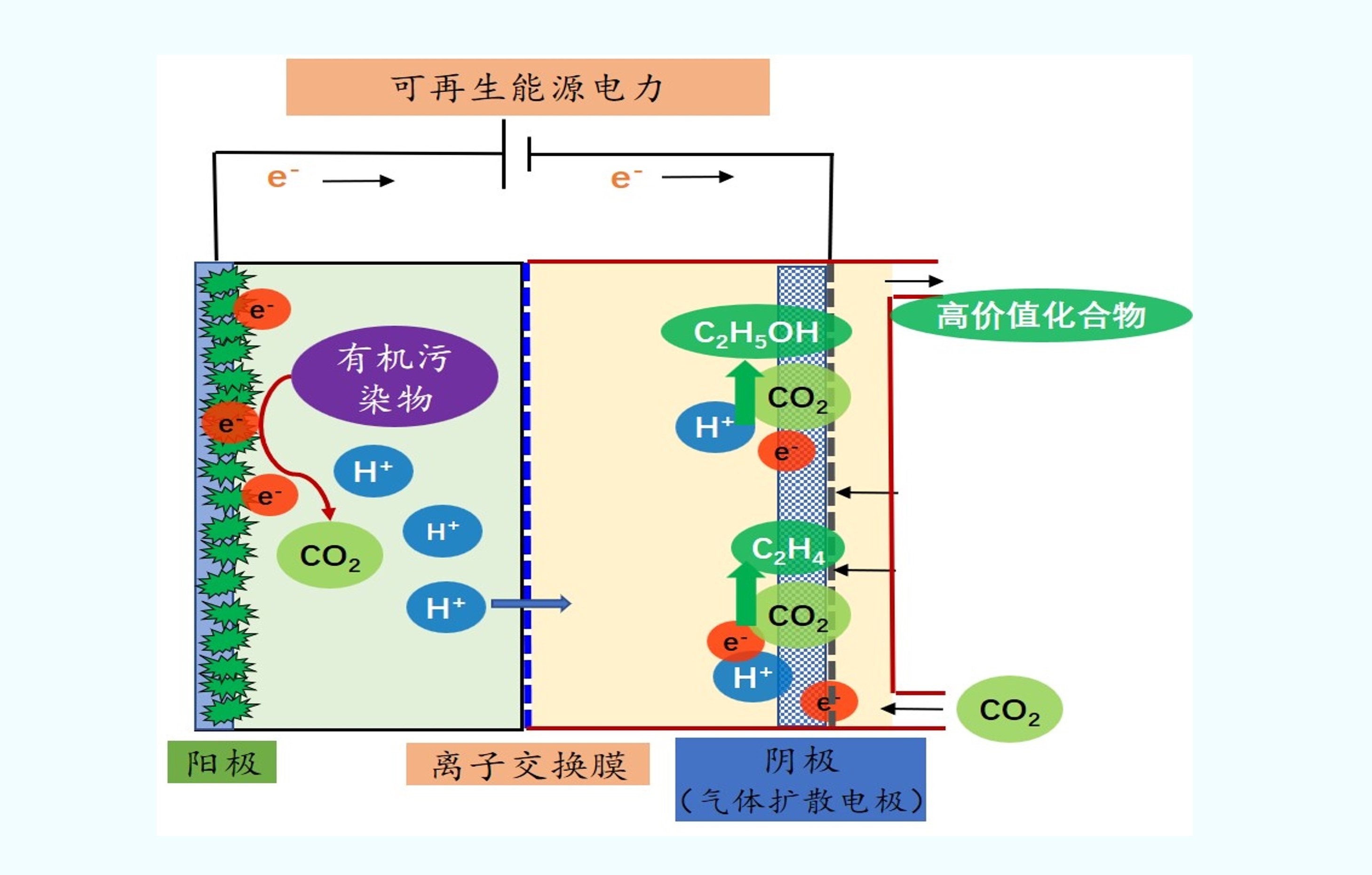

Traditional wastewater treatment processes emit a large amount of greenhouse gases, such as the United States and China, where the current net emissions are about 13.5 and 14.9 MtCO2e, but with reasonable design, wastewater treatment can become a carbon capture and utilization process, achieve carbon neutrality, or even become a carbon-negative process. We can convert carbon dioxide to valuable chemicals, such as methane, formic acid, ethylene, and ethanol, through electrochemical reduction or microbial processes. If we use the renewable energy and the wastewater to power these systems, these processes can also be used to store renewable energy.

All-3D-printed electrochemical cells

全3D打印电化学反应器

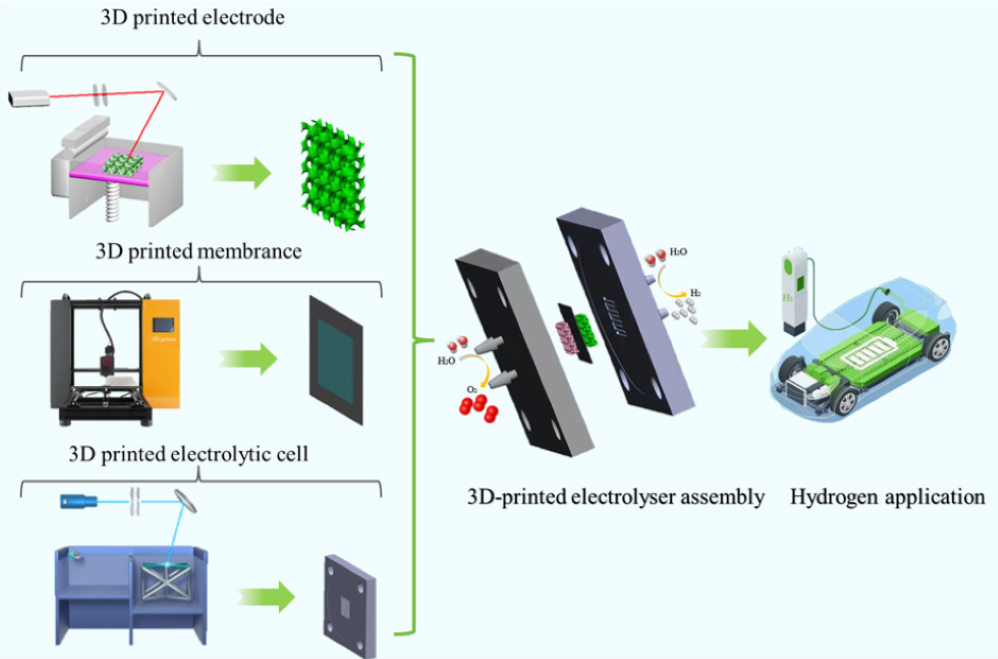

An all-3D-printed electrochemical cells consisting of electrodes, membrane, and electrolytic cell is manufactured by 3D printing technology. The hierarchical porous electrode fabricated by 3D printing with a large specific surface area can be designed with effective gas-solid-liquid three-phase interfaces. Furthermore, bubbles attached to the electrode surface can be carried timely by optimized liquid channels in the 3D printed electrolytic cell, which can increase mass transfer rate and effective catalytic efficiency. The low-cost 3D printed membrance not only ensures the material transmission and gas separation but also has excellent mechanical strength and durability. The all-3D-printed water electrolyser with the above advantages has great potential and feasibility in large-scale industrial applications.

Desalination and water recovery via hydrogels

水凝胶用于脱盐及污水回用

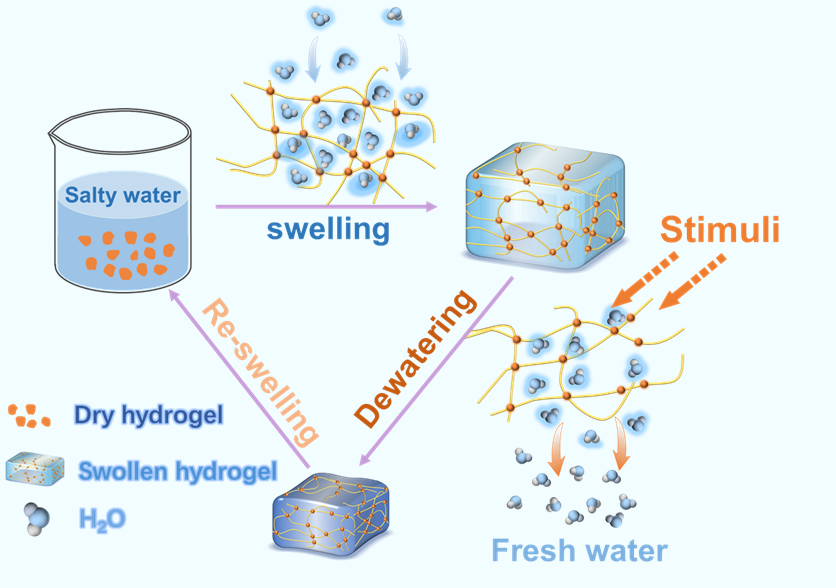

Water scarcity has become one of the significant environmental challenges affecting the sustainable development in our country. Hydrogel materials, as a type of three-dimensional network polymer material with the merits of easy preparation, low-toxicity, and reversible shrinkage-swelling properties, have attracted widespread attention in the fields of desalination and wastewter recovery. Our PAAM hydrogels contain numerous hydrophilic groups, enabling them to absorb water up to several hundred times their own weight. The releasing of the absorbed water molecules can be realized through certain stimuli, which is reversible. Through optimizing hydrogel monomers, crosslinking density, charging groups and dehydration approaches, the performance could be further improved. This hydrogel-based desalination and water recovery technique is promising for the reuse of unconventional water sources and alleviate the freshwater crisis.